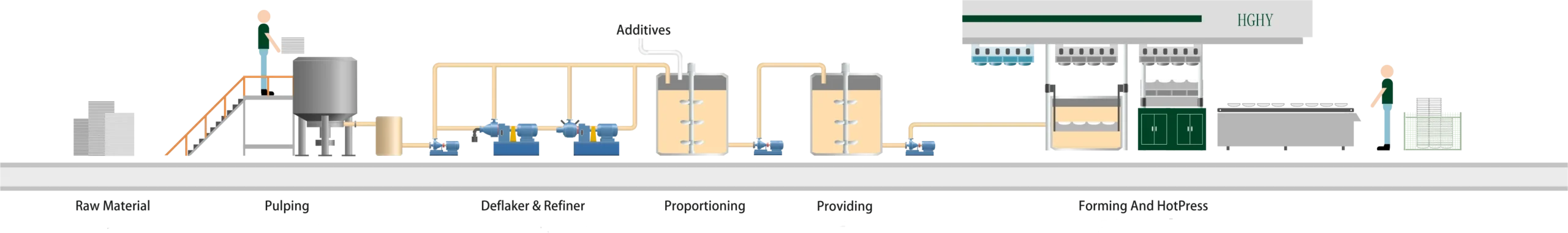

Pulp ECO Packaing Machine

Specialized equipment that use heat and pressure to mold pulp into eco-friendly, biodegradable packaging such as trays, clamshells, plates, and containers, widely applied in the food industry, electronics, and consumer goods.

Daily Capacity: Base On Products

Main Features

Pioneering the development of high-end IP thermoforming technology since 2002, this solution is ideal for producing premium inner and outer packaging for crafts, mobile phones, daily essentials, cosmetics, digital products, and more.

Made from renewable plant fibers such as bagasse, wheat straw, reed, and moso bamboo, it supports a wide range of applications including 3C digital product packaging, cultural and creative goods, high-end gift boxes, furniture and cosmetic packaging, wine bottles, instruments, medical devices, paper cup lids, and milk powder spoons.

Technical Parameters

| Model | ZJWD-9575 | ||

|---|---|---|---|

| Product Application | Inner Lining Packaging is Increasingly the Preferred Choice for 3C Digital Products, Cultural and Creative Products, Premium Gift boxes, Cosmetics, and More. | ||

| Daily Capacity | Base On Products | ||

| Platen Size | 950 × 750 mm | ||

| Heating Energy | Electricity / Thermal Oil | ||

| Forming Method | Reciprocating | ||

| Hotpress Method / Pressure | Hydraulic System / Max 30 Tons Pressure | ||

| Safety Protection | Self-locking & Auto-stop Design | ||

| Max Product Height / Thickness | 115 mm / 1.2 mm | ||

Great Feature

- High precision and stability ensure consistent, high-quality production. The integrated forming and hot pressing design streamlines the process, while offline automatic trimming enhances efficiency and finish.

- This system is capable of producing inverted cup lids (less than 0 degrees), meeting unique and specialized packaging needs.

- With precise control over position, pressure, and temperature, it is ideal for manufacturing a wide range of high-end packaging products.

Rapid Mold Change

Designed for producing high-quality, eco-friendly molded fiber packaging, this system supports small draft angles (≥0.5°) and radii (≥0.3). It includes a prepress for negative angles, ensuring precision, accurate positioning, and stable operation across various high-end packaging formats.

High Efficiency

Equipped with a fully automatic PLC control screen and powered by an energy-efficient servo motor, the system is user-friendly and cost-effective. Two-stage hot press stations enhance production capacity and quality, ideal for premium packaging needs.

Optimized Output

Offering a high return on investment, the system achieves a daily production capacity of 650–800 kg, depending on product specifications—perfect for scaling sustainable packaging operations.

Our Clients from the World

Asia :China,South Korea,Vietnam,Thailand,Philippines,Malaysia,Indonesia,Singapore,India,Iran,Saudi Arabia,Yemen,Kazakhstan,Uzbekistan,Turkmenistan,Iraq,Oman,Lebanon,Syria,Azerbaijan

Europe:Britain,France,Denmark,Poland,Czech Republic,Hungary,Ukraine,Russia,Turkey,Albania,Serbia,Slovakia,Belarus,Lithuania,Estonia,Austria

South America: Colombia,Ecuador,Brazil,Bolivia,Chile,Argentina,Uruguay

Central America:Honduras

North America:United States,Mexico

Oceania:Australia,New Zealand

Africal: Egypt, Libya, Algeria, Morocco, Tunisia, Mali, Sudan, Nigeria, Cameroon, Uganda, Madagascar