Semi-automatic Tableware Machine

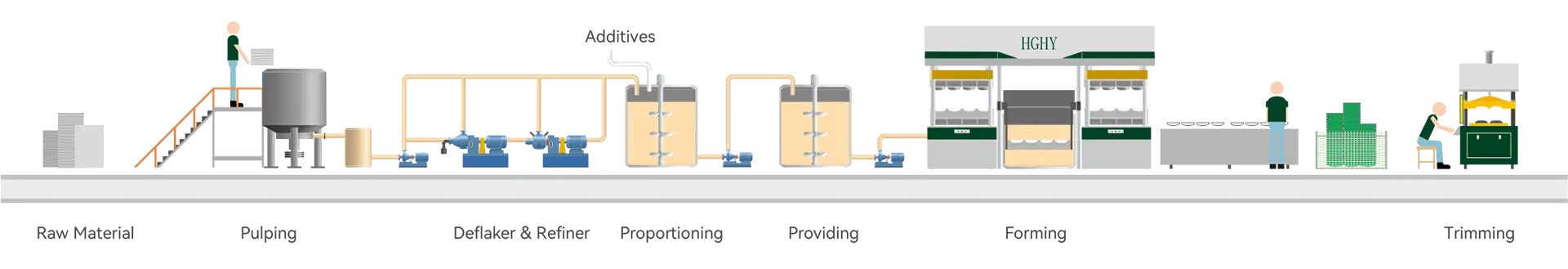

Semi-automatic bagasse tableware machine offers a balanced solution between manual and fully automated systems — combining efficiency, ease of use, and affordability, ideal for medium-scale production and growing businesses.

Main Features

Semi-automatic bagasse tableware machines offer a cost-effective solution for medium-scale production, blending automation with manual operation to boost efficiency. Ideal for businesses transitioning from manual to streamlined processes, these machines help optimize productivity and reduce costs in the growing eco-friendly tableware market. Using renewable plant fibers like bagasse, wheat straw, reed, and bamboo, the equipment produces a variety of sustainable products including plates, lunch boxes, bowls, cups, hamburger boxes, and premium egg cartons. With over 100 units sold, this advanced technology showcases the power of automation—imagine 10 robots working in harmony in one factory.

Technical Parameters

| Model | BW2-9895C | ||

|---|---|---|---|

| Product Application | Disposable Tableware, Paper Cups, Premium Egg Carton | ||

| Daily Capacity | 500 KG ( Base On Products ) | ||

| Platen Size | 980 × 940 mm | ||

| Heating Energy | Electricity / Thermal Oil | ||

| Forming Method | Reciprocating | ||

| Hotpress Method / Pressure | Hydraulic System / Max 30 Tons Pressure | ||

| Safety Protection | Self-locking & Auto-stop Design | ||

| Max Product Height / Thickness | 60 mm / 0.8 mm | ||

Great Feature

- Flexible, precise, and stable machinery designed for safe, simple operation with low investment — adaptable to various tableware manufacturing needs.

- Incorporates energy-efficient systems, preventive maintenance, and smart facility layout to reduce operating costs and enhance productivity.

- Includes bulk material purchasing, workforce training, and waste minimization to ensure consistent supply, skilled operation, and sustainable production.

Operational Efficiency

Upgrade to energy-efficient systems and optimize facility layout to lower utility bills and streamline workflow. Regular preventive maintenance ensures equipment longevity and reduces unplanned downtime.

Cost Control

Cut expenses by purchasing raw materials in bulk for consistent supply and better pricing. Reduce material waste through recycling and efficient production practices.

Workforce Optimization

Invest in training programs to enhance operator skills, boost productivity, and minimize human errors on the production line.

Our Clients from the World

Asia :China,South Korea,Vietnam,Thailand,Philippines,Malaysia,Indonesia,Singapore,India,Iran,Saudi Arabia,Yemen,Kazakhstan,Uzbekistan,Turkmenistan,Iraq,Oman,Lebanon,Syria,Azerbaijan

Europe:Britain,France,Denmark,Poland,Czech Republic,Hungary,Ukraine,Russia,Turkey,Albania,Serbia,Slovakia,Belarus,Lithuania,Estonia,Austria

South America: Colombia,Ecuador,Brazil,Bolivia,Chile,Argentina,Uruguay

Central America:Honduras

North America:United States,Mexico

Oceania:Australia,New Zealand

Africal: Egypt, Libya, Algeria, Morocco, Tunisia, Mali, Sudan, Nigeria, Cameroon, Uganda, Madagascar